Manufacture of parts for railway equipment

Layout development of railway stations, depots, junctions, hauls, passing-tracks, bridges and track structures. Manufacturing modern and historical rolling stock and equipment models (locomotives, steam locomotives, mainline locomotives, electric locomotives, draisines, railcars, carriages, platforms).

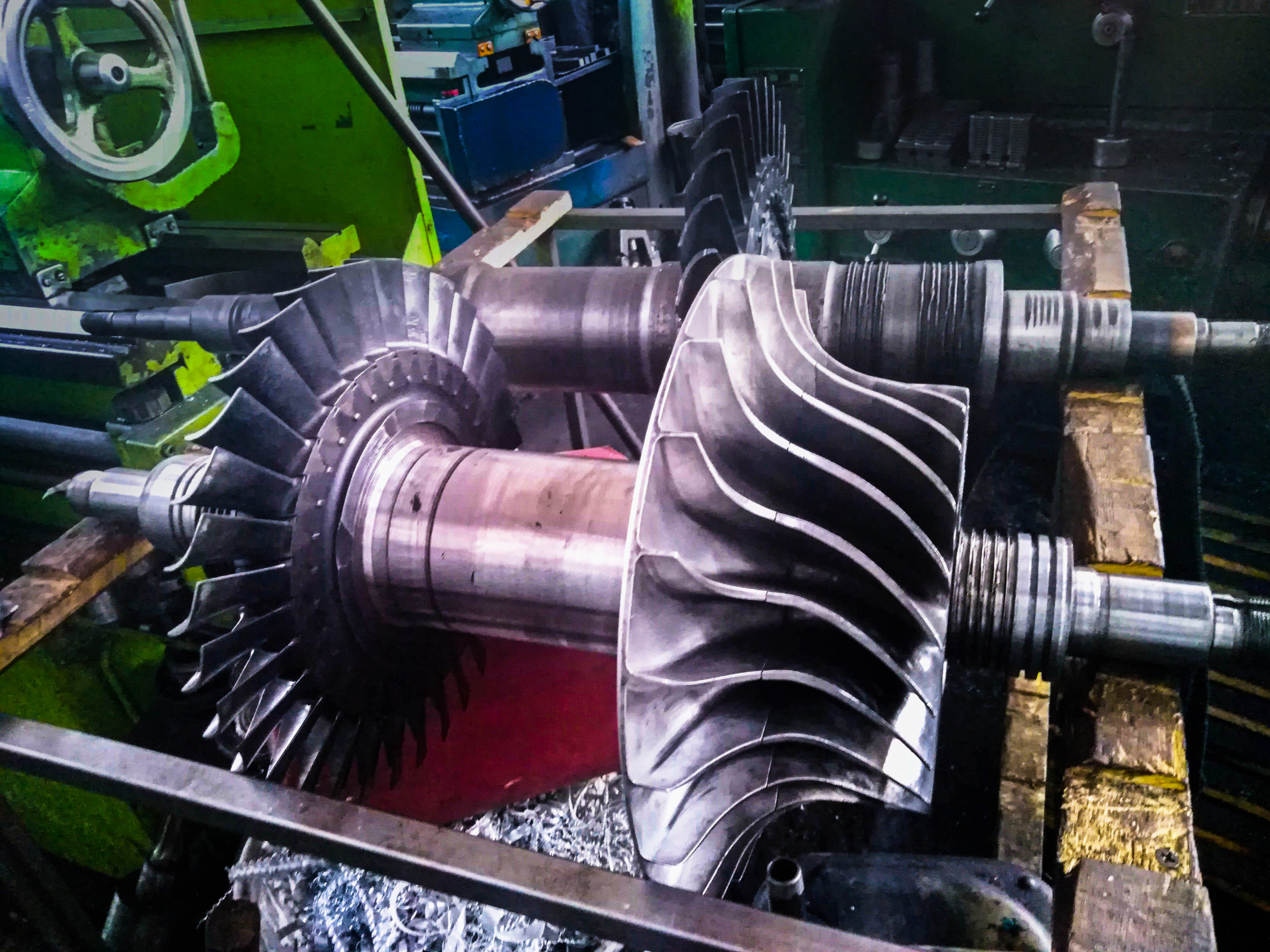

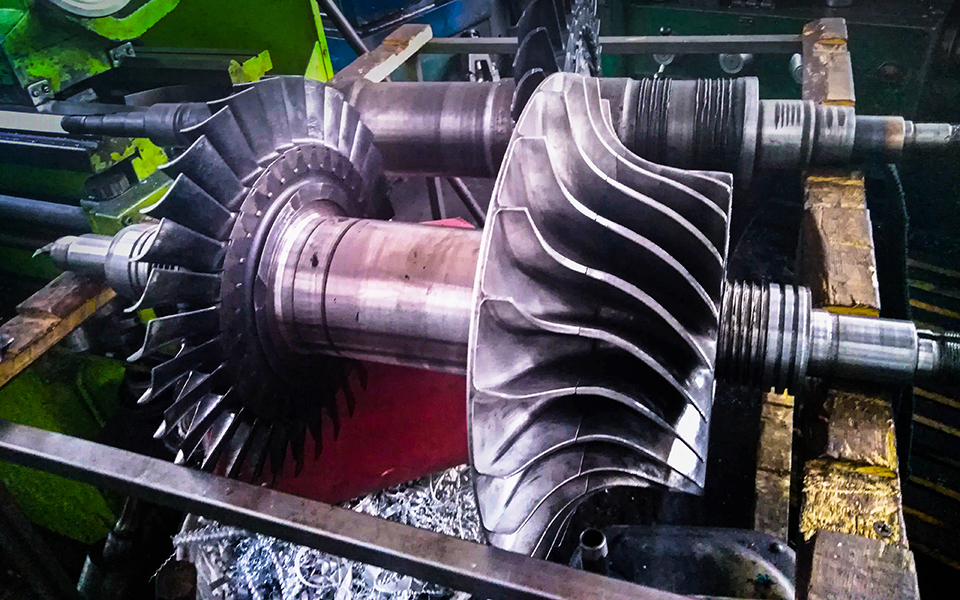

Manufacturing of turbocharger parts

Often due to improper operation, the turbocharger needs to be repaired. Turbine parts have to be changed due to the use of poor-quality engine oil in the car engine, careless maintenance of the car, or for other reasons

Component repair and assembly

Assembly of components, aggregates, and the car requires many operations. This usually involves the assembly of threaded, press, keyed, splined, cone joints, gears and bearing assembly.

Welding and thermal treatment

Various processes are performed during the construction of metal structures. Weld heat treatment is, for instance, performed during the working process with metals and their alloys. This allows to change their properties and structure. For heat treatment of welded joints, a specific tool is used, depending on the selected method. Cleaned metal can be processed.

Bryansk Railway Equipment Plant

BZGT LLC was founded in 2003 with the prospect of development major repairs of locomotive equipment, manufacturing spare parts for railway transport. The primary customer throughout the plant activity is JSC Russian Railways, its branches and industrial facilities of the Russian Federation.

Today, BZGT LLC is a harmoniously developing production complex with facilities located in a separate building with an area of 2200 sq.m, which includes more than 30 units of different blanking and machining equipment, a balancing machine, technological equipment for turbochargers testing, wash and spray paint complexes, NC department, welding and assembly sites. The entire production complex has the necessary communications, is equipped with lifting-and-conveying equipment.

The company’s capabilities make it possible to repair up to 40 units of diesel turbochargers of any modifications, up to 20 units of different types of gearboxes, and manufacture more than 200 types of spare parts for diesels Д49, Д50, 10Д100 and locomotives of types ТЭМ2, ТГМ4, ТГМ6 every month.

All work performed is carried out in accordance with the requirements set forth by JSC Russian Railways and is controlled by the inspection of the Technical Audit Center (TAC).

Piston TEM2.85.12.133

Piston TEM2.85.12.133...

Worm wheel TEM2.00.20.251

TEM2.00.20.251 worm wheel – 1100 rubles!...

TEM flange2.85.10.259

TEM flange2.85.10.259...